Funfrap Saves Money and Reduces Its Carbon Footprint with Sinto’s Green Sand to Core Sand Reclamation

Customer Background:

Funfrap foundry is located in the city of Aveiro, Portugal and it is part of the Teksid Group, producing 45.000MT of cast iron automotive castings, mainly cylinder blocks/ heads, differential housings and other parts for customers such as Renault, Fiat, Chrysler and PSA and Honeywell. They are a certified ISO/TS16949, ISO14001, OHSAS18001 and ISO5001. The plant was also the first iron foundry of the FCA group to be awarded, in November 2015, the WCM Bronze Award.

https://www.teksid.com/en/iron/plants/aveiro

Customer Need:

With increasing demands for casting quality, rising landfill costs and the need to reduce environmental impact, reclaiming greensand proceeding from the existing molding line to be reused in the core shop was a logical step forward.

The Solution:

Following extensive secondary attrition trials at our Peterborough pilot plant, the decision has been made to place an order for a 10 t/h reclamation plant, consisting of a vibratory feeder, BD attrition unit, sand drier & cooler, before conveying the greensand to 3 x USR (RSR) 10.1 secondary attrition units and a cooler.

Most importantly, the new order is marking the first step away from the “thermal reclamation”- approach within the Teksid Group and towards a greener, more environmentally friendly reclamation technology with a significantly reduced CO2 footprint.

The new unit will be operative early 2021, ensuring Funfrap has the latest technology available to meet & exceed the demand for a cleaner, greener and cost- effective sand reclamation.

Project Equipment:

Section 1 – Sand Attrition & Drying

1.01 1 Vibratory Feeder; 10tph 5.0 x 0.6m

1.02 1 BD 20 Attrition Unit

1.03 1 Fluid Bed Sand Drier; Model 10

1.04 1 G6 Cooler/Classifier;

1.05 1 G6 Fan Silencer and Attenuation;

1.06 1 DP200 Pressure Vessel;

1.07 1 Electrical Control Panel;

1.08 1 Allen Bradley 5000 series controls (BD & drier)

Section 2 – Secondary Attrition USR (RSR)

2.01 3 Vibratory Pan Feeder;

2.02 1 Drum Type Magnetic Separator 10 t/h

2.03 3 USR (RSR) 10.1 Secondary Attrition Unit;

2.04 1 G6 Cooler/Classifier

2.05 1 G6 Fan Silencer;

2.06 2 DP200 Pressure Vessel;

2.07 1 Electrical Control Panel;

2.08 1 Allen Bradley 5000 series controls

Green Sand to Core Sand Reclamation – Background Information

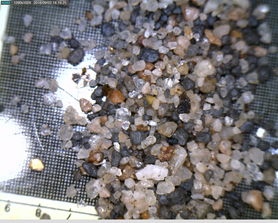

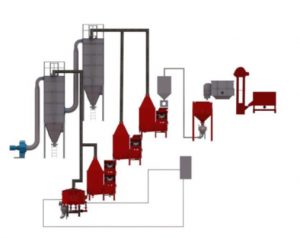

Traditionally, green sand to core room reclamation is accomplished utilizing a combination of pneumatic sand impingement on a steel target, followed by a thermal reclaimer, a cooler/classifier and possibly an additional mechanical reclamation treatment. However, Sinto’s RSR based reclamation system is efficient enough to not require the upfront capital and permitting expense and high ongoing operational costs of a thermal reclaimer. Instead, Sinto’s system is able to effectively and efficiently utilize the sand or ceramic media’s natural scrubbing action in combination with high speed ceramic rollers to remove clay, carbon and other contaminates that would be normally detrimental in the core room. A micrograph of RSR reclaimed sand is shown in Figure 1 along with a field photo in Figure 2 and a model of a RSR system in Figure 3.

Figure 1: Reclaimed silica sand after USR (RSR) reclamation.

Artificial Ceramic Foundry Sands

When OSHA enacted their new Permissible Exposure Limits (PEL) limits in 2018, many foundries started seriously considering switching to ceramic media in their no-bake or green sand operations to minimize silica exposure. In order to efficiently make the switch to ceramic media sands (normally mullite or bauxite based), the foundries needed a method of reclaiming their spent sands back to the core room. Traditional mechanical reclamation is normally satisfactory for no-bake, but for green sand, mechanical reclamation followed by thermal calciners has been the standard for many years. Upfront investment costs of several million dollars and high long term operational costs have made these heat based systems unobtainable for many foundries. With the introduction of the RSR system, foundries are finally able switch to ceramic media based green sand systems, with much lower upfront investment and operational costs. In fact, some foundries have calculated that by putting in an RSR and switching to ceramic media, their sand and operational savings pay for the upfront investment in equipment and ceramic media in less than 1-3 years depending upon core usage. This quick Return on Investment (ROI) in combination with the reported improved surface finish and reduced burn-in/burn-on are driving the growth in ceramic sand conversions. For more information on this, please contact Sinto America at sales@frohnnorthamerica.com or www.SintoAmerica.com.

Figure 2: Showing a RSR in a green sand foundry.

Figure 3: Green sand to core sand system featuring a series of three USR (RSR) reclaimers, sand storage, bag house and scalping screen.

ABOUT Sinto America

Roberts Sinto Corporation is a part of Sinto America, Inc., the North American group holding company, of Sintokogio, Ltd., Japan. The Sinto group of companies has an international reputation for excellence in the foundry, manufacturing and surface treatment industry. With over 80 years of experience providing state of the art systems to industries worldwide and its comprehensive offering of engineering, equipment and turnkey solutions, Sinto is well positioned to provide the optimum value to the meet the challenges of the metal casting industry.

Sinto America focuses on six primary markets- Foundry, Sand Processing, Bulk Material Handling, Automation, Surface Technologies and Surface Treatment. Sinto also provides contract blasting and precision shot peening services through our National Peening and Technical Metal Finishing divisions.

Learn more at www.frohnnorthamerica.com

Contact: sales@frohnnorthamerica.com or (517) 371-2460

Want to know more about Sinto’s Green Sand to Core Sand Reclamation?