Domite Wear Technology Sees Benefits of V-Process Casting Technology

Grand Ledge, MI – April 24, 2020

Casting finishing with new HWS V-Process line on left vs. casting finishing with old no bake line on right.

Domite Wear Technology, located in Paris, Ontario, Canada, has been seeing the many benefits of their newly installed HWS Sinto V-Process System with Turntable and Shaketable Station. Domite is an ISO 9001:2015 certified corporation that has been supplying wear plates and wear liners for the mining and aggregate industry for over 30 years. Learn more about Domite at https://domite.com/.

Sinto completed installation on the new equipment in quarter three of 2019. Since then, Domite has been at full force, with the first production run of ~10,000 lbs of wear plates, out of the v-line, being completed in March 2020.

Domite’s vacuum molding machine has a 1270 x 1270 x 250/250mm flask size, producing 2-4 molds per hour. Previously, their castings from the no bake line required manual cleaning, grinding and still had a rough surface finish. Now, their castings from the V-Process are more accurate with less grinding and have a very smooth surface. “We have been able to lower the previously intensive labor and finishing costs by 75% and the end product is a beautiful casting” – Andrew Guiducci, President, Domite Wear Technology Inc.

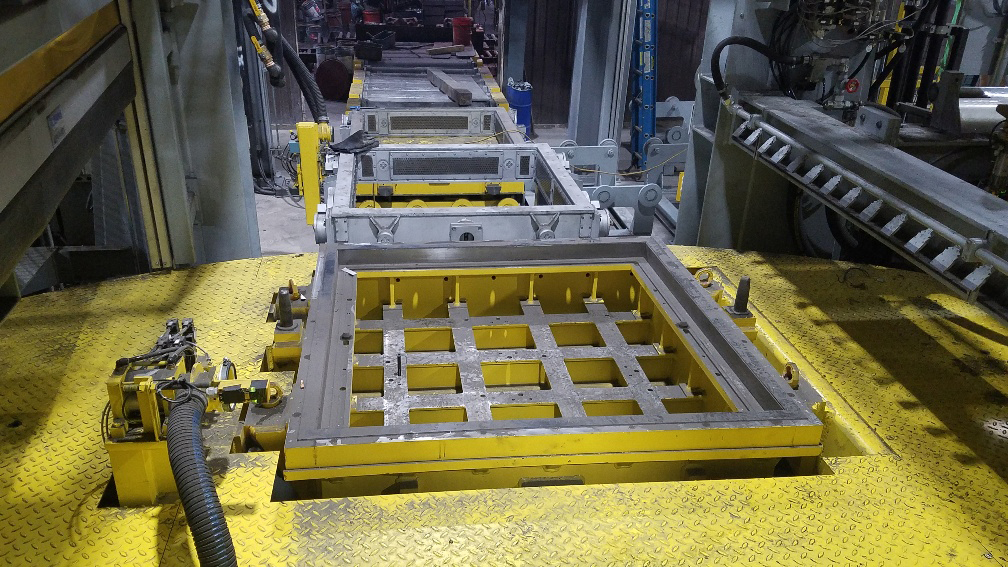

Master Bolster Frame on Turntable for Building Cope and Drag Flasks

Turntable System Indexes to next Mold Making Position for Assembly of Cope and Drag Flasks

Empty Flask Return to V-Process Mold Line

V-PROCESS MOLDING MACHINE FEATURES:

- Elevated molding and pouring heights to allow for automatic sand collection and easy clean-up

- High quality and excellent dimensional accuracy through sand forming technique in which sand is sealed in plastic film and hardened by vacuum suction

- Excellent mold consistency and repeatability

- No pattern wear and no need for draft

- No movement of the mold wall due to high mold hardness

- No mold deformation by volatile mold sand additives

- Cooling process can be influenced by switching on and off vacuum and reducing internal stress inside of casting

- Plain, non-coated sand; no preparation or sand reclamation needed

- Eliminates outside cores and shake-out process

HWS Sinto is the only design and manufacturer of V-Process Casting Technology. The Sinto team worked side by side with Domite to test the feasibility of the process with their casting and to provide a solution that stayed within their budget.

The Sinto America team is looking forward to seeing Domite Wear Technology lead the way in supplying premium wear resistant material to the mining and material handling industry throughout the world and supporting them throughout the years to come.

ABOUT HWS

Heinrich Wagner Sinto Maschinenfabrik GmbH (HWS), based in 57334 Bad Laasphe, is a globally active machine construction company that develops and produces sophisticated and technically high quality machinery and systems for the foundry industry. Since 2003, HWS has been a 100% subsidiary of SINTOKOGIO – a partnership that has developed into a major success story. Today, HWS is a market leading manufacturer of moulding systems, moulding machines and system technologies for the production of highly compacted moulds for modern foundries.

ABOUT Sinto America

Sinto has long strived to be the leader in the design and manufacture for all foundry, metal finishing and shot blasting applications. From standard to custom, simple or complex, or a single piece of equipment to a full system, that’s the Sinto difference, your one stop solution.

Sinto America, Inc. is the North American group holding company, of Sintokogio, Ltd., Japan. The Sinto group of companies has an international reputation for excellence in the foundry, manufacturing and surface treatment industry. Sinto America focuses on six primary markets – Foundry, Mold and Core Making, Sand Processing, Automation, Surface Technologies and Surface Treatment. Sinto also provides contract blasting and precision shot peening services through our National Peening and Technical Metal Finishing divisions and cut wire abrasives through our Frohn North America division. Learn more at: www.frohnnorthamerica.com.

Contact: sales@frohnnorthamerica.com or (517) 371-2460

Want to know more about Sinto’s V-Process Mold Machines?